Future technological developments are highly dependent on the invention/engineering of materials. Sustainable/environmentally friendly/energy-efficient materials processing is the key for future technological developments. Our research focuses on the development of green/energy-efficient/sustainable processes to fabricate advanced materials (two-dimensional materials, nanomaterials) for energy, environment, and healthcare applications. The group work can be divided into the following subsections:

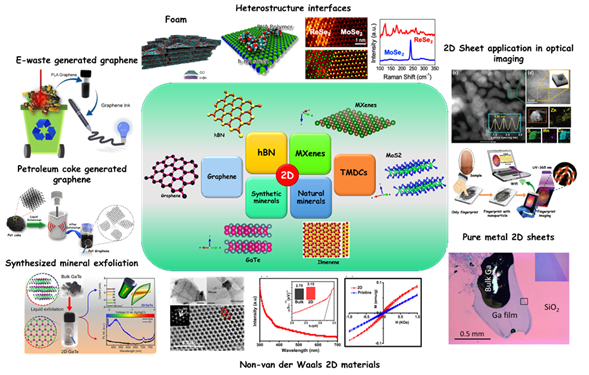

(i) Innovative and unique two-dimensional materials as sustainable energy materials

Our initial work on the development of graphene-based (G-hBN, G-ZrO2, G-Fe2O3, etc.) unique 3D porous architecture with up to 95% porosity consisting of high-surface-area (>1000 m2g-1) and significant mechanical strength. These materials are shown to have great potential for engineering applications in electronic devices and energy harvesting, environmental cleaning, and bio-medical. Then, we worked on alloying 2D TMDs with several immiscible elements (Sn, Re, Te, etc.) to engineer the band gap, phase transformation, and stacking of the layers. We extended the alloying to multi-element (Mo, W, S, and Se) 2D structures and synthesized different stackings of these multi-element TMDs with tunable bandgaps. The alloying has enabled 2D materials with unique optical, electrical, and magnetic properties, which have been utilized by several groups across the world to develop smart sensors and electronic devices.

The team has synthesized new 2D metals (e.g., gallenene (2D-Ga), tellurene), which are one of the early 2D metals in the community and show high surface-based chemical and electronic properties. A new area in 2D community started with the work of exfoliation of non-Van der waals or non-layered materials from natural ore (i.e. Hematene (2D-hematite), ilmenite, chromite, etc.). The atomically thin 2D-oxides show unique electronic, magnetic, and catalytic properties, which are utilized in various applications in sensors, hydrogen production, and catalytic activity. We extended the idea and demonstrated the possibility of exfoliating several non-layered telluride materials such as SnTe, CoTe, CoTe2, Co2Te3, MnTe, MnTe2, Cr2Te3, CrTe2, Bi2Te3, NiTe2 etc. We also initiated a new area of 2D-silicate from natural ore and synthesized 2D-Biotite, Rhodonite, Vivenite, Mascovite, Florite, Galena, Pyrite and phosphate etc. These naturally extracted 2D materials show exciting flexoelectric/triboelectric properties, which can be utilized for green energy harvesting and catalysis.

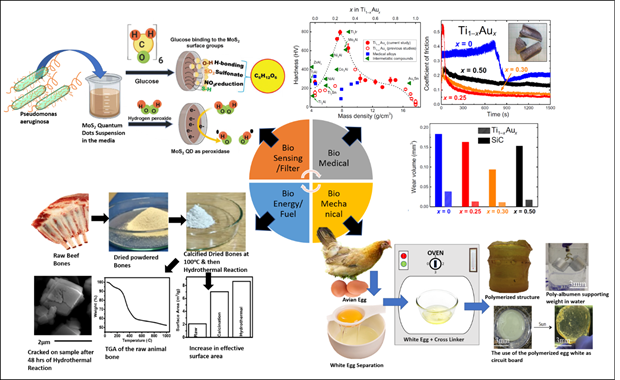

The team led the team to develop a green and sustainable method to synthesize 2D materials (CdS, MoS2, NbC, and graphene) using microbes at normal conditions without any energy or harsh chemicals. These green and sustainable materials are unitized for glucose, ammonia, and other bio-based sensors. In the list of 2D materials, there are limited metals. The team synthesized 2D-Alumunium and titanium alloy using bulk quasicrystals. The high surface area and charge materials are utilized for hydrogen production and plasmonic-based sensing.

(ii) Green-manufacturing and smart/energy-efficient manufacturing of materials

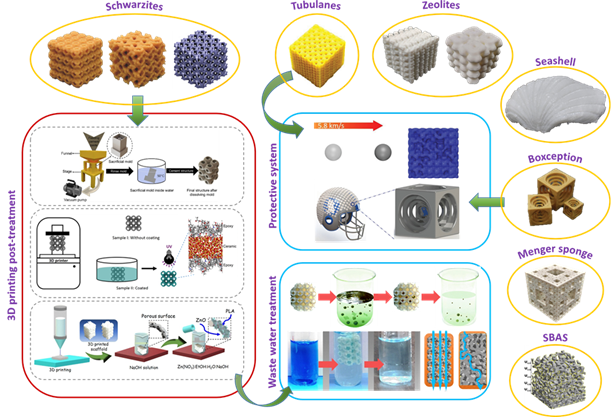

The team has established two major work directions in the 3D printing area. The first of these works aimed at unraveling the shape evolution in nature, such as seashells, octopus cups, anthills, etc. 3D printing techniques were used to recreate the various structures. By combining experiments to determine the stress distribution with finite element modeling, it was possible to establish a correlation between shape evolution and animal survivability inside these architectures. The second work was related to tuning the material topology to build porous and stiffer architectures inspired by atomically rough/curved shapes, e.g., schwarzites, tubelene, zeolite, etc. The conclusions from these studies can be the basis for creating better and safer architectures and/or protective structures with high specific strength and impact resistance. The team has developed multi-material printing, which can print site-specific using different materials. Based on the simulation, the high stress/strain locations in a complex architecture can be replaced with different materials, which results in extraordinary mechanical and thermal properties. The team’s series of papers in this area has opened up a new direction in the additive manufacturing community.

The group has developed a direct ink writing method to print various materials such as graphene, oxide, metal, and composites. The recent paper in this area has pushed the limit of achieving controlled porosity (100 microns) with the highest resolution along with enhanced toughness and thermal resistance in alumina and silicon carbide. The 3D printing structures show multifold enhancement in mechanical resistance with high specific surface area. The team also utilized the 3D-printed ceramic, metal, and polymeric architecture as a substrate for coating 2D materials for water treatment, environmental cleaning, and robust electrics/sensors. The group also has utilized 3D printing to develop unique alloys consisting of immiscible elements. The series of papers in this area consisting of Cu-graphene, Cu-hexagonal boron nitride, and Cu-Ta/W/Nb/W has opened up a new alloy system consisting of immiscible elements. 3D printing/additive manufacturing has been utilized to build these alloys, which is not possible by conventional methods. These alloys show high strength, thermal transport, wear, and catalytic properties. The work is working in the direction of AM, which can replace assembly in manufacturing and smart, energy-efficient processes. The team’s group has recently used DIW to fabricate half-Heusler thermoelectric alloys, supercapacitors, and hydrogen electrodes as well. The group is working with industries and ISRO to explore unique printing technologies.

(iii) Sustainable materials technologies

The team has developed a zero-waste technology, which led to the success of major society-relevant research on the recovery and recycling of e-waste. We have shown that cryomilling (low-temperature grinding) easily separates the metallic and polymeric components by converting them to colloids, which can subsequently be fully recovered without the need for any burning process. The team has extended the recycling process and developed high-entropy multicomponent alloys from metals recycled from e-waste, which are further utilized for catalysis (environmental cleaning). The team also developed technology that utilizes plastic waste to synthesize graphene with high conductivity. Currently, the team is working with a startup and developed a supply chain to collect e-waste from houses and recycle it in large quantities (100 kg/day). Also working with metal recycling and plastic companies to achieve zero disposal e-waste recycling.

The team has developed a unique and easily scalable cryo-mill (KC0) that can operate at cryogenic temperatures. The conventional ball mill results in micron-size particles with nano grains (with limited surface area); also, the high temperature (during milling) results in chances of contamination. The team’s low-temperature ball mill results in free-standing nanoparticles with high surface area and negligible contamination. We demonstrated the synthesis of large-scale metallic/non-metallic systems such as Cu, Fe, Mn, Ag, Ni, ZnO, ZnS, NaCl, KCl, LiCl, and CNT, etc. These high surface areas of these particles are utilized for several applications in catalysis and environmental cleaning. The same technique has been utilized for the synthesis of multicomponent high-entropy alloy nanoparticles with controlled sizes and shapes. The team started exploration of high entropy alloys for energy and environment applications and published a series of papers on high entropy alloys for catalysis and environmental applications. Based on the understanding, the team, along with his collaborators, developed a low-cost catalyst using earth-abundant structural elements for hydrogen production. The team also developed converting agricultural waste into green carbon for coating application. India is an agricultural-based country and produces lots of waste, which results in environmental pollution. The team has designed and developed a unique process consisting of physical, chemical, and thermal treatment that produces Green Graphene (high surface area carbon with low thickness). The anti-corrosion performance of the composite coating results in higher corrosion resistance than uncoated carbon steel. The composite coating shows improvement in surface roughness, hydrophobicity, and hardness. The team has scaled up with a start-up partner to industrial scale. The pilot-scale plant is taken up/adapted by lead paint companies. These eco-friendly materials, created through environmentally conscious processes, can be a safe alternative to the conventional toxic chemicals used to protect against corrosion in marine environments.

Bio-inspired innovative sustainable materials development

Nature always designed materials with well optimized structures/architectures. The optimum mechanical and functional properties can be observed in different natural materials. In the current project, the team tried to understand such materials and design bio-inspired materials. We utilize waste materials to develop/synthesize unique green materials using energy-efficient and low-cost processes.

Materials Science and engineering for society

Under this theme, we would like to explore the possibility of usages of our materials understanding to solve the problem for society/humanity. We have been working on beneficiation of e-waste using environmental friending techniques, porous materials for CO2 absorption and conversion of waste materials into useful energy source etc.

e-waste, Tiwary et. al. Mat. Today 2017